1:50 structural model

1. Prepare digital model

With references to photos and drawings of the Taoyuen Greenhouse, a digital 3D model was built in revit to prepare for the fabrication.

Only the main structure is modelled as it is the selected element to be fabricated for structural studies.

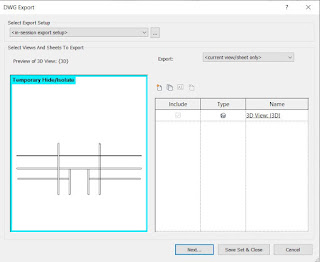

2. Prepare laser cut files

Drawings in CAD format are exported from the revit model for the preparation of files for laser cut.

The material chosen is 2.0 mm basswood with a board size of 800x450mm

Exported drawings of components of the structural frame are arranged in Autocad for laser cut.

3. Laser cut

Components are being cut on a basswood board.

4. Assemble

Parts are Assembled by hand with glue.

5. Final model

2. Green Square community and cultural precinct

1:1000 site model

1. Collect site information

Site information including height of the buildings, building types, width of streets, current conditions...are collected by site visits, the acquirement of official documents and drawings/maps available online.

2. Prepare digital model

With references to photos and drawings of the site, a digital 3D model was built in revit to prepare for the fabrication.

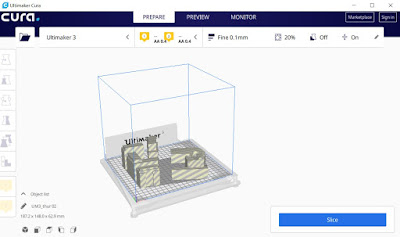

3. Prepare 3D printing files

Revit models of buildings are exported to stl files for 3D printing using a plug-in.

The stl files are arranged to fit the cura 3D printing machine.

4. 3D printing

The buildings are arranged in three different files for the cura machine to print.

Each part takes around 8 hours.

5. Collect 3D print and clean up

Models are collected form the machine and touch-ups like polishing the edges are done before assembling them with the base

6. Prepare laser cut files for the base

Light score is used to indicate roads on the site.

7. Laser cut for the base

4.3mm corrugated cardboard is chosen as the base material.

4 boards are stacked and glued to create a base with a thickness

8. Assemble the buildings and the base

The buildings are plugged into the carved out space of the base.

9. Finished model

3. Sky Greens (Rotational vertical farming system)

Representative model

1. Draft design

After discussions, tutor provides me with a draft design of the model and a concept revit model is built based on it to identify design components.

2. Production of component

i/ Wheels

A bike chain wheel is taken as reference. The size and shape of is measure and the whole form is duplicated by laser cutting basswood.

ii/ Chain

Bike chain is used and it is broken into sections for plugging in screws to hold racks.

2 different ways are explored to break the chain.

First is using a grinder to remove the top part of the chain component, then remove the pin inside.

The second way is to use a chain breaker to push the pin out.

iii/ Main frame

The main frame is fabricated by laser cutting 3mm basswood

iv/ Rack

The racks are fabricated by laser cutting 2mm acrylic

3. Assemble

The components are then being assembled to form the main body.

4. Motor

A electrical motor is assembled and connected to the wheel's rod to perform the rotational movement.

5. Adding final details and plants to the model

6. Final model